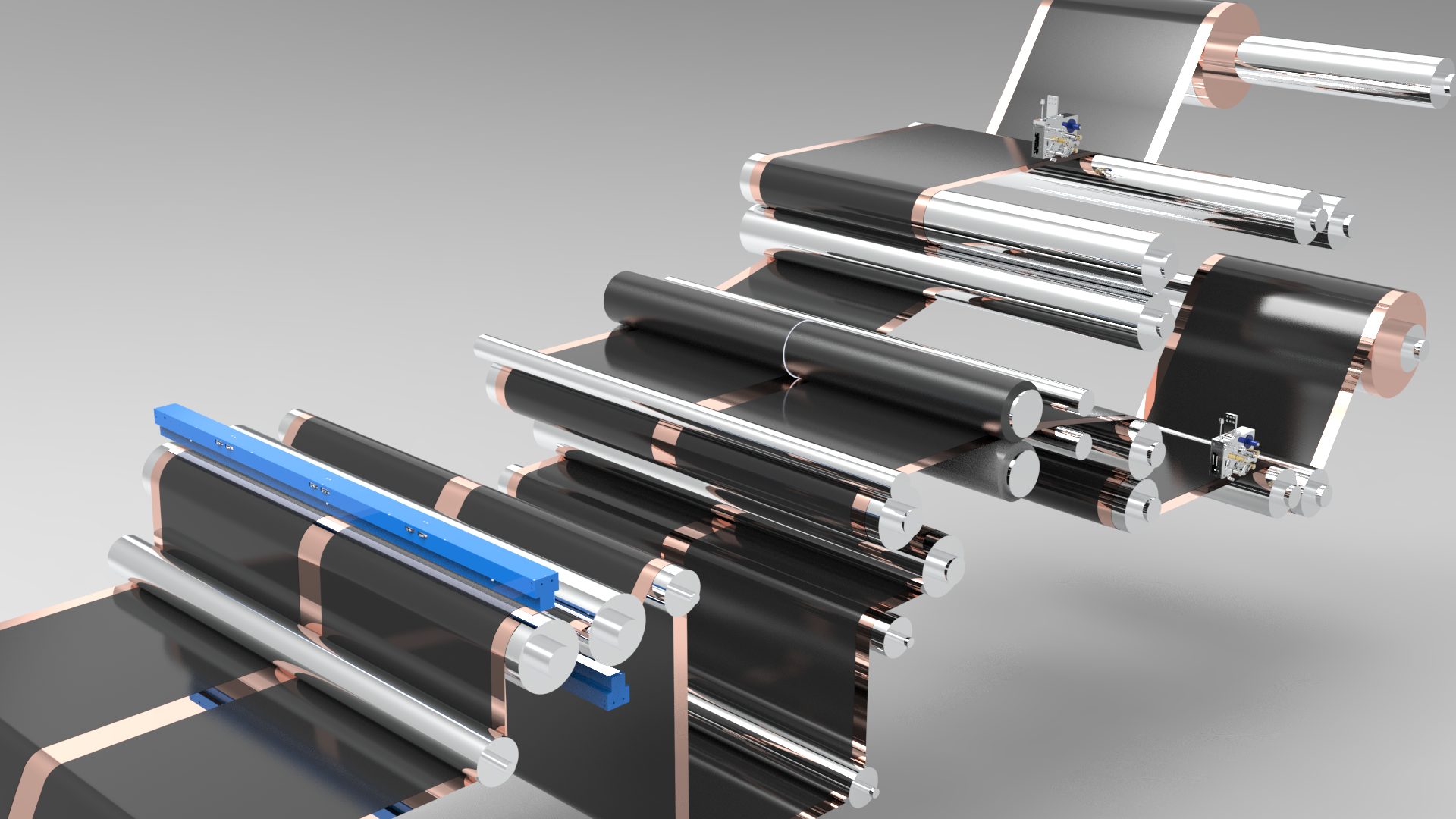

Vision inspection system applied to battery winding process

Winding machine is one of the core equipment in the middle stage of lithium battery production. Its main

task is to stack positive and negative electrode sheets, separators and other materials in turn and wind

them into cylindrical or square cells. During the winding process, defects such as battery tab wrinkles and

electrode misalignment will seriously affect the performance and safety of the battery.

The vision inspection system can accurately identify various defects on the pole piece and PE film

coating, such as scratches, cracks, stains, foreign bodies, pinholes, dimensional deviations, etc. If

these defects are not discovered in time, they will lead to a decline in lithium battery performance, shortened lifespan

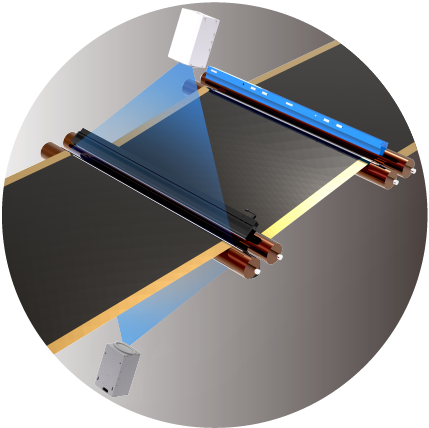

and even safety issues of lithium batteries. Through the real-time monitoring of the vision inspection

system and the communication linkage control of the winding equipment, defective pole pieces or

diaphragms can be discharged after a single roll, thereby reducing raw material waste, improving the

overall product yield and effectively improving the equipment utilization rate.