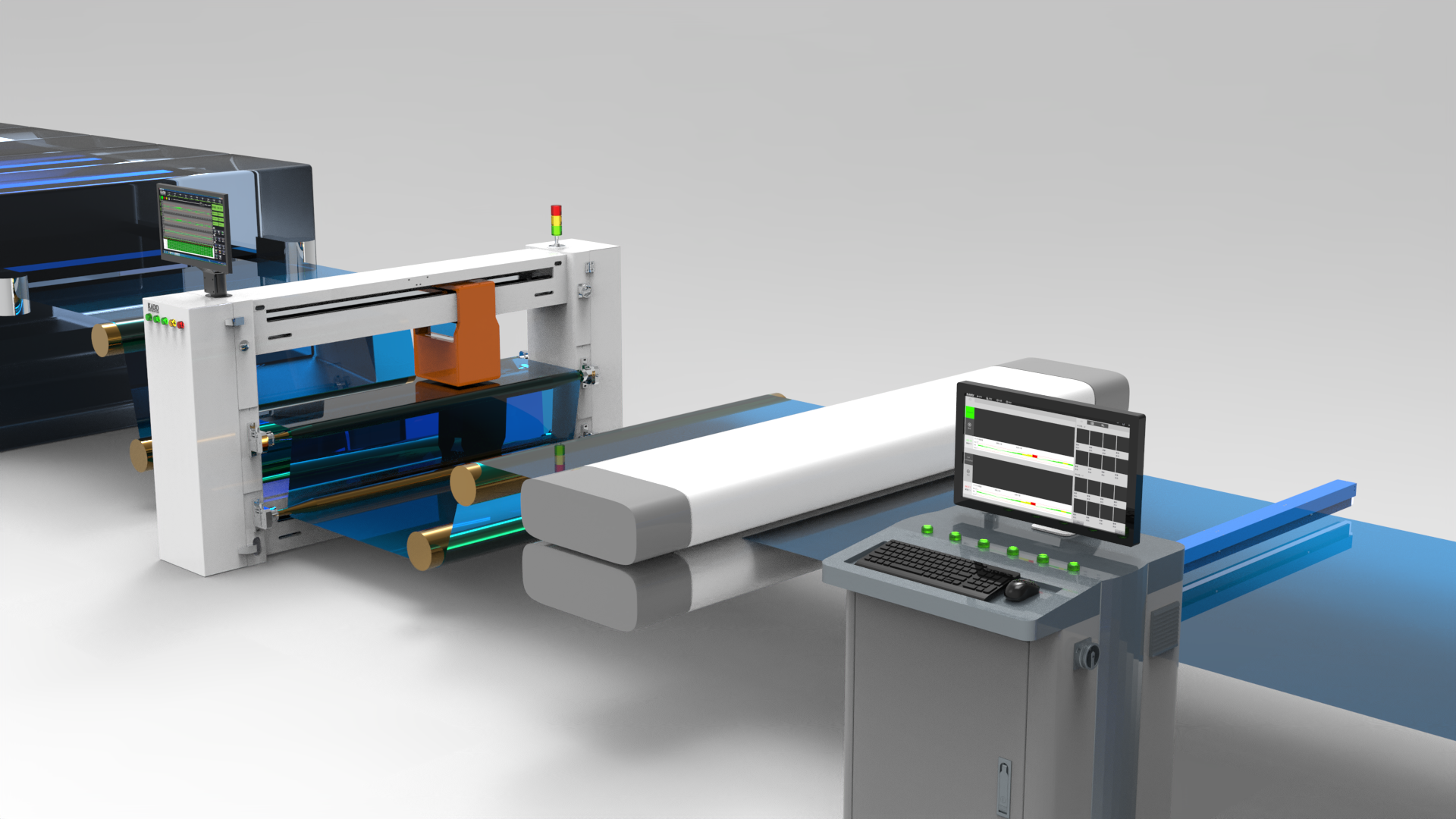

Online thickness measurement system applied to double-drawing production line

The online thickness measurement system is precisely embedded in the biaxially oriented film production line to achieve real-time thickness monitoring during the production process. The system uses non-contact laser or ultrasonic technology to measure the thickness of each point of the film at high speed to ensure product uniformity, optimize material consumption, and improve the yield rate. Real-time feedback data helps the production line to adjust quickly, ensure stable product quality, meet the market demand for high-precision films, and improve production efficiency and competitiveness.